Have you ever noticed you get a receipt after an ATM transaction; similarly, you go to the superstore and get a small receipt of payment; where they come from, how they are produce, what is the manufacturing process of the thermal paper?

According to history, the paper is a Chinese invention dated back to 105 AD. These days’ lots of different types of papers are available in the market, but we are only sticking to the thermal paper industry in our business ideas category. Thermal paper was invented in the USA in 1968; however, it was not a reality until 1971 when Japanese companies used it in real production. Interestingly Japan invented the first slitting machine.

According to Fortune Business Insights, the thermal paper global market size was 3.45 billion US dollars in 2019. The European Association of Secure Transactions reported 14.5 million POS terminals deployed in Europe for business transactions.

What is Thermal Paper?

It is a special paper that prints information without any kind of ink due to heat printers. This process is done by using heat-sensitive dyes and special color developers during the manufacturing process of the thermal paper.

Market Size and Usage of Thermal Paper

The market size was 3.45 billion dollars in 2019 and it con be increased by 6.9 percent per year and reach up to 5.85 billion dollars in 2027 according to the data and increasing in Asian markets.

We all know that paperless transactions are increasing globally day by day. On the other hand, the use of thermal paper is also increasing globally because of cost-effectiveness. Asia is the most growth region for the thermal industry. There are many benefits to using thermal paper for business transactions.

Now we talk about the usage of thermal paper;

By Industries;

Retail Industry

Logistics

Banks

Medical

Gaming

It is worth mentioning that the retail and logistic industry is highly dependable on thermal papers due to their low-cost printing capability.

Common Use of Thermal Paper;

- POS

- Tags and Labels

- Ticketing

- Lottery and Gaming

- Medical

- Others

- Bank’s ATMs

Before we dig into the business plan of the thermal paper, we will also discuss the manufacturing process of the paper. It could be a little technical for you but if you are reading this article to start a business of thermal paper roll; it is highly beneficial that you have this knowledge.

Read the benefits of thermal paper

In this post, we will discuss the small thermal paper roll for end consumers and will not discuss the jumbo thermal paper roll business.

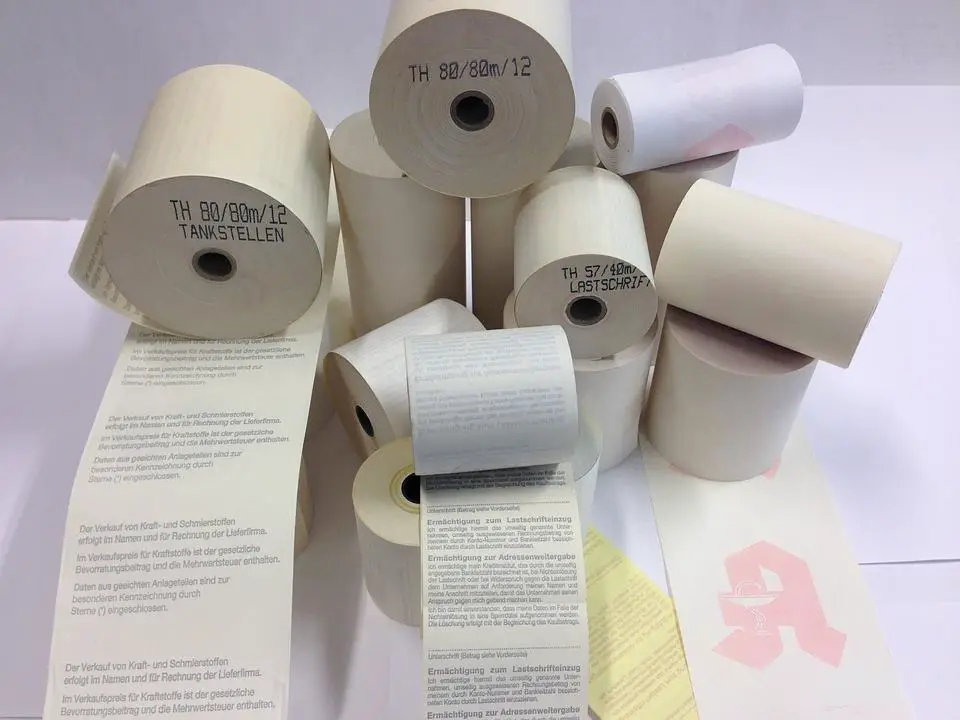

There are some standard sizes available in the market globally for different kinds of industries.

That is 80mm x 80mm, 57mm x 57mm, 44 x 60mm or even 38mm x 40mm, and some other sizes. So when you want to manufacture the thermal roll keep these sizes in mind to avoid any kind of investment loss.

Manufacturing Process of the Jumbo Thermal Roll Paper

There are four kinds of imaging chemicals used in the manufacturing of jumbo thermal paper rolls. These are as follows;

Leuco dyes

Leuco dyes can switch between two chemical forms, one of which is colorless. The dyes used in the thermal paper are usually triaryl methane phthalide dyes or fluoran dyes or Crystal Violet lactone. These dyes have a colorless leuco form when crystalline or when in a pH-neutral environment, but become colored upon melting or when exposed to an acidic environment.

Developers

Developers are organic acids, which are melting along with leuco dyes in order to provide more color. Examples of such developers include phenols, sulfonylureas, and Zinc salts of substituted salicylic acids. Traditional thermal paper uses BPA as an acid developer but due to some scientific reports this acid can absorb into the body and can affect fertility, for this reason, European authorities took action and ban the BPA acids and most of the manufacturers in Europe turned to BPS acid in the thermal paper manufacturing process.

Sanitizers

Sensitizers are use to add to the paper surface to optimize the colorization temperature and to facilitate the mixing of developers and leuco dyes upon melting. Sensitizers are commonly simple ether molecules.

Stabilizers

Stabilizers are use to add in order to stabilize the layer or glass formed by the leuco dye, developer, and sensitizer and prevent the dyes to return to their original colorless, crystalline forms when stored in hot or humid conditions.

Material Required For Manufacturing

- Slitting machine (according to needs)

- Jumbo roll (paper features as required)

- Accessories (cores, packing materials, etc)

- Skilled labor

Paper Features

- Basic properties: weight, thickness, moisture properties

- Strength properties: tensile and tearing strength, elongation

- Surface properties: brightness, whiteness, smoothness/roughness, strength

- Absorption properties with different liquids

Manufacturing Process of Small thermal paper rolls.

To start manufacturing thermal paper rolls for industry, you must need the jumbo roll and the slitter rewinder machine according to your need.

Generally, a jumbo roll contains 6000 meters approximately, and from that roll, you can make a finished roll that is generally available at 15, 25, 40, 50, and 70 meters long in the market.

Regarding thermal paper slitter rewinder, it is a kind of shear cutting machine, that is using for making POS, ATM, cash register, NCR, ECG, and plotter rolls. As an electromechanical integrated device, it consists of unwinding, transmission, slitting, rewinding, and controlling sections.

In order to purchase the most suitable thermal paper slitter re-winder, you must be aware of several parameters.

The 1st is your jumbo roll width, once your thermal paper jumbo roll width is confirmed, you could choose 500mm, 700mm, 900mm, 1100mm, or 1400mm width machine according to the jumbo roll;

The 2nd is jumbo roll diameter, Maximum 1000mm unwinding diameter is supported generally;

The 3rd is slitting width, the world’s mainstream thermal paper roll width is 57mm and 80mm at present, but it can be changed as per your customer base. Generally, you do not need other sizes for sale in the first phase, when the business grows your customer base can increase and you might need the other sizes.

79mm x 79mm paper rolls are mainly used in ATM cash machines, while 57mm x 40mm rolls are widely used in POS machines. These sizes are occupying 80% of the total market.

The length can easily adjust through HMI PLC test panels that come in modern machines, once your required length is complete machine stops and you need to put another shaft for another roll and the process continues with repetitions until your production requirement is finished.

For width, you need to set up the spacers with a blade in slitters according to your size requirements i.e. 79mm or 57mm.

Some machines also come with flexo printing options on the backside for promotional purposes. Modern machines can also make rolls without a core to save the cost of the roll.

Thermal Paper Roll Business Overview

After technical discussion, we are going to talk about the business plan, cost, and financials of the thermal paper slitting business.

Machine Cost

The machine is available from $10000 to $50000. The prices depend on the manufacturer’s location in India, USA, China, Germany, etc, and functionalities like color or non-color. capacity and many other factors.

Area Required for the Production

Consider the small business with one machine, office, and the space for raw material and finished product we will suggest the minimum area you are required to start the business is 300 sq ft. It can get on rent or purchase as property.

Skilled Labor Requirement

In the beginning, your business can start from one skilled labor only but as you grow, you may need another helper for one machine to get the manufacturing process fast. It is better that your labor understand a little basic electromechanical knowledge, the slitting machine is not difficult to operate, but it also needs you to understand the most basic electrical principles.

Power and Weight

The electrical power of the machine with no color is generally required 2.5 kW, and with color, it can go up to 3.5 kW, as far as the weight concern without color it is approx 1.2 ton and with a color option, it is i.5 ton.

The market

The market has lots of consumers of thermal paper due to its cost-effectiveness, some of them are mentioned below.

- Banks

- Retail Stores

- Logistics companies

- Restaurants

- Cinemas

- Others

Competition

There is no high competition available in the market due to a lack of awareness and cost. Also, most of the customers are repeat customers.

Advertising Methods, Pricing, and Sales Strategy

Lots of advertising channels are available to grow your market, such as website, social media, physical visiting, cold emails and calls, local newspapers, signboards, etc. For pricing and sales strategy always follow the local competitor in the first stage of your business and once you start growing you will understand the game and act accordingly.

Other Necessary Overheads for Production

Packaging material, cores (either plastic or corrugated material if required), etc.

SWOT Analysis of the Thermal Paper Roll Business

| Strength | Opportunities |

| 1. Potential of the market 2. Repeated Customers 3. Low Competition | 1. Market future is a good 2. Opportunity to explore new customers every day |

| Weakness | Threats |

| 1. No Experience 2. Capital | 1. Production cost 2. Competition 3. Local legal, power, and capital issues |

Thermal Paper Roll Business Setup Approx. Initial Cost

| Set-up costs US Market | |

| Setting up the business | |

| Accountant’s fees(Yearly) | $1,000 |

| Solicitor’s fees (One time) | $700 |

| Business registration | $300 |

| Domain name registration and Hosting (Yearly) | $500 |

| Insurance premiums (One year) | $700 |

| Licenses | $500 |

| Workers’ compensation (3 months) | $6,000 |

| Setting up the premises | |

| Lease deposit and advance rent | $3,000 |

| Fitout | $2,000 |

| Utility bonds and connection | $1,000 |

| Stationery and office supplies | $1,000 |

| Plant and equipment | |

| Equipment | $20,000 |

| Vehicles | – |

| Telecommunications | – |

| Computers and software | $1,000 |

| Starting operations | |

| Advertising and promotion | $2,500 |

| Raw materials and supplies | $10,000 |

| Working capital | $5,000 |

| Start-up capital | |

| Equity investment | $30,200 |

| Borrowings | $25,000 |

| Total | $55,200 |

*The above report is based on US market pricing. However, these expenses are the same to start a business in all countries you can research the local pricing and make decisions accordingly.

Read the benefits of thermal paper

Manufacturer of Jumbo Thermal Paper Rolls in the USA

The famous supplier of jumbo rolls in the US is as follows;

Mark Adjetey

Manufacturer of Jumbo Thermal Paper Rolls in Europe

Koehler (Germany)

Manufacturer of Jumbo Thermal Paper Rolls in China

APP

Chenming

Guanhao

Thermal Paper Roll Slitting Machine Manufacturer in China

Jota

Bogle

Thermal Paper Roll Slitting Machine Manufacturer in India

WEBTECH

Vinayaka Paper Products

Accurate Engineers.

Is thermal paper business profitable?

In short, Yes, the market has great potential with repeat customers all over the world. It requires a small investment but with great profit, especially with color machines that can be used for promotional material on the back, this can help for upselling with extra profit.

How do I sell thermal paper rolls?

There are multiple channels to sell your product.

- Direct selling

- Online

- Through distributors

- Cold calling and emails to large corporates

What is thermal paper used for?

Thermal paper is a special paper that prints with heat from the thermal printer. The image is produced by heat, without printing ink, when the selected area of the thermal paper passes over the thermal print head. It is commonly used in Banks, Retail, and the logistics industry. The common uses are POS, ATMs, Ticketing, etc.

Can I use thermal paper in a normal printer?

No, it is not recommended to use thermal paper in a normal printer due to its nature that is slippery and thin than normal printer paper.

How long will thermal paper last?

If stored below 77 degrees it can last up to three years without printing, after printing it can last up to 7 years.

The basic goal of “The Business Goals” is to help the entrepreneurs’ community in achieving their goals and business objectives by providing the authentic and latest entrepreneurial ideas.